Our Production Process

A transparent, accelerated and advanced way of production.

Procurement of Raw Materials

Our expansive 4500-square-foot raw material storage facility is designed for efficient inventory management. We ensure that only high-quality materials are used, subjecting them to rigorous inspections before they proceed to the manufacturing stage. This attention to detail is critical to maintaining the integrity of our casting process and subsequent production stages.

Melting and Pouring

A critical step in the casting process is the pouring of molten metal into centrifugal dies. By precisely regulating the temperature and RPM during this phase, we achieve uniformity and structural strength in our Cylinder liners , Cylinder blocks of engines , Cylinder liner sleeves , Engine cylinder sleeves , Both dry and wet cylinder sleeves. This meticulous process ensures that every product delivers superior performance and durability.

Centrifugal Die-Casting

We, at Myron liner LLP, do Centrifugal die-casting, also known as rotocasting, is a metal casting process that uses a spinning mold to create cylindrical parts. The process involves pouring molten metal into a spinning mold, where centrifugal force distributes the metal evenly along the mold's inner diameter. The metal then solidifies from the outside in.

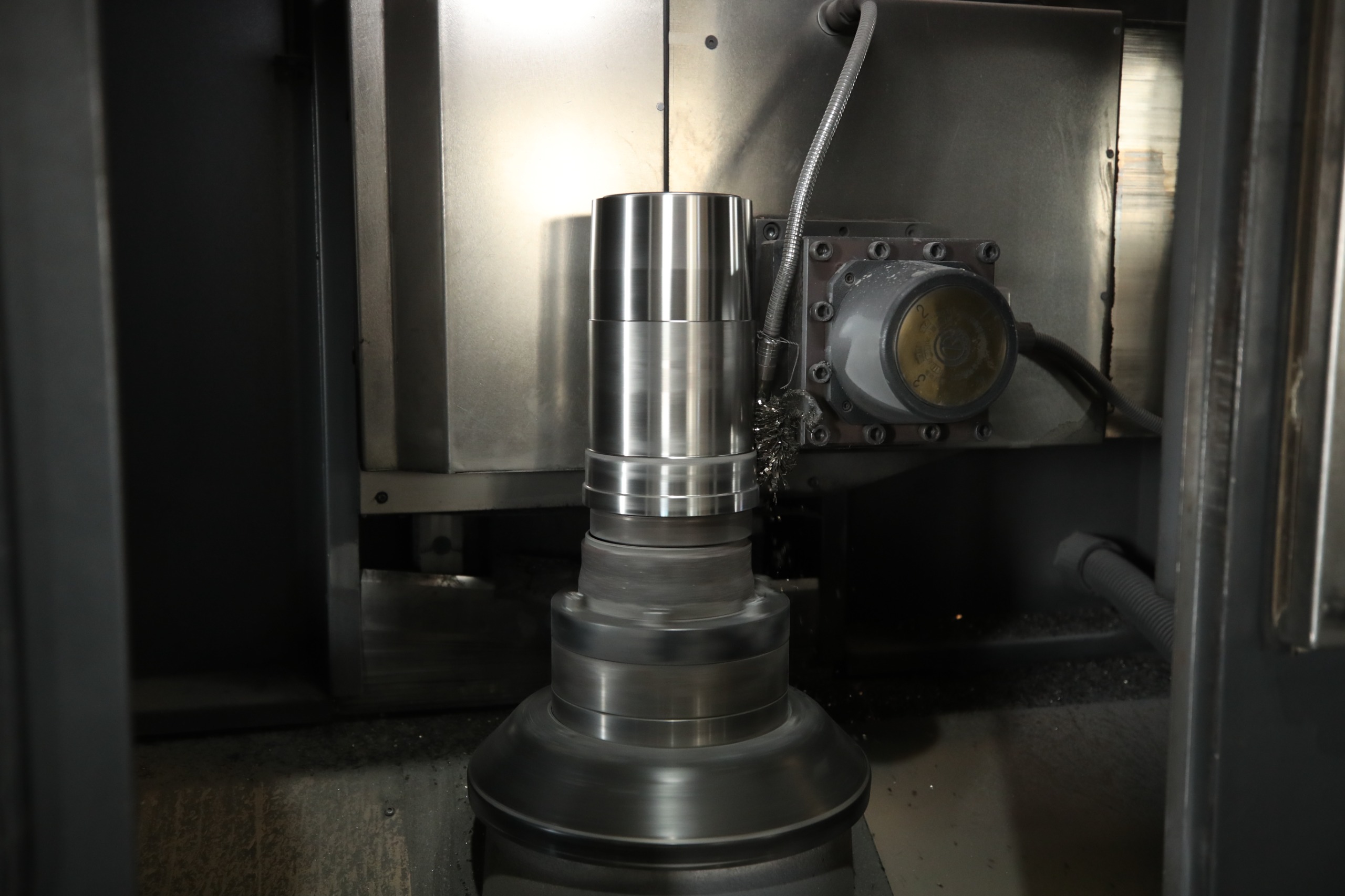

Machining Workshop: Precision and Perfection

Our machining workshop is a testament to our dedication to precision engineering. Spanning an impressive 45,000 square feet, this facility houses cutting-edge equipment such as:

• CNC VTL Machines

• CNC Machines

• Centerless Grinding Machines

• Plateau Honing Machines

• CNC Boring Machines

• CNC Turning Machines

The integration of advanced technologies allows us to perform intricate machining tasks with exceptional accuracy. A key focus in our workshop is the grinding process, which ensures the smoothness and precision of our cylindrical components. Our cylindrical grinding operations use specialized tools to achieve the desired dimensions and surface finishes, enhancing the performance and longevity of our products.

Honing Process

We, at Myron liner LLP, do Honing process , it's a finishing process that uses abrasive stones to improve the surface quality, dimensional precision for our Dry and Wet Cylinder Liners, Cylinder Sleeves and Air Cooled Blocks.

Grinding Process: Refining Perfection

The grinding process is a critical step in the production of Cylinder sleeves,. Our advanced centerless grinding machines and specialized cylindrical grinders deliver unparalleled precision. This process not only refines the dimensions but also enhances the surface finish, ensuring optimal performance in various applications.

Quality Control: The Cornerstone of Excellence

At Myron Liner LLP, quality is not just a process—it’s a philosophy. Our comprehensive Quality Check process is integral to every stage of manufacturing, ensuring that every product leaving our facility meets stringent quality standards.

Advanced Packing Area

Our packing area spans 18,000 square feet and features automated ultrasonic cleaning machines. This ensures that all finished products are free from contaminants and ready for immediate use. Our organized storage and efficient packaging systems are designed to provide our customers with a seamless experience, ensuring that every shipment arrives in pristine condition.

Foundry: The Backbone of Manufacturing

At Myron Liner LLP, we take immense pride in our state-of-the-art infrastructure, which is meticulously designed to deliver high-quality Cylinder liners , Cylinder blocks of engines , Cylinder liner sleeves , Engine cylinder sleeves , Both dry and wet cylinder sleeves, and a wide range of precision-engineered products. Our commitment to innovation, excellence, and sustainability is reflected in every aspect of our manufacturing process, from raw material procurement to final product delivery. With a robust facility spread across a sprawling area, we ensure seamless operations through advanced technology and skilled craftsmanship.

Raw Material Storage

Foundry

Pouring

Machining Excellence

Our CNC VTL Machines , CNC Machines , Centerless Grinding Machines , Plateau Honing Machines , CNC Boring Machines ,CNC Turning Machines ensure precision and consistency in every product. Through meticulous machining, we achieve dimensional accuracy that enhances engine efficiency and longevity.

Advanced Packing Area

Our packing area spans 18,000 square feet and features automated ultrasonic cleaning machines. This ensures that all finished products are free from contaminants and ready for immediate use. Our organized storage and efficient packaging systems are designed to provide our customers with a seamless experience, ensuring that every shipment arrives in pristine condition.

Metallurgical Lab

Spectrometer

Within our infrastructure, we adhere to stringent practices for raw material inspection, ensuring meticulous monitoring of chemical composition to enhance the durability of liners for prolonged service life.

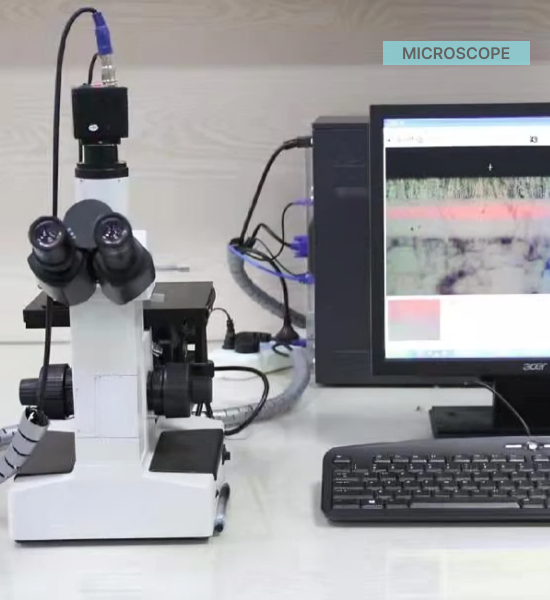

Microscope

As part of our operational practices, we utilize microscopes to scrutinize the microstructure of liners, diligently maintaining the graphite structure. This commitment contributes to enhancing the strength of our liners, showcasing our company's dedication to quality and performance.

Hardness

In our commitment to delivering superior quality liners, we employ a hardness tester to meticulously inspect the hardness of our products, ensuring that our customers receive liners of the highest quality.